Made by Parker Filtration a leading maker of diesel fuel filters the LifeGuard LG100 three-stage separator is the most advanced vent-spill preventer we tested. The fuel level of your tank changes throughout the day even if you are not driving it.

A Tank Vent Valve should allow air to enter the tank to replace the volume of fuel volume exiting the tank without allowing fuel to be lost through the vent system.

Marine fuel tank vent system. Attwood 90 Degree P-Trap Fuel Tank Vents. These vents help prevent water from entering the fuel tank yet allow air to vent freely during normal sea conditions and washdowns. This eliminates the need for an anti-siphon loop in the vent hose.

Meets ABYC StandardAttwood 90. A Tank Vent Valve should allow air to enter the tank to replace the volume of fuel volume exiting the tank without allowing fuel to be lost through the vent system. Where is the vent valve located.

The Evaporative Emission EVAP Canister Purge Solenoid Valve is located in the EVAP canister above the rear of the muffler. Your tank has to breathe. In order to breathe your tank must have a vent somewhere that will relieve both vacuum and pressure.

Gasoline expands in volume as it warms up and shrinks in volume as it cools down. The fuel level of your tank changes throughout the day even if you are not driving it. When you open the vent on an expanded tank fuel vapors will escape.

If the tank is sucked in opening the vent will allow air into the tank to equalize the pressure. For safety reasons opening the vent should be done off the boat on a level surface with good air circulation in the area and no ignition source present even cell phones. Ensuring a predetermined level in the tank eliminates traditional vent leakage from the fuel expanding due to the daily temperature rise.

This also protects the carbon canister located in the vent line from becoming saturated with liquid fuel. There are some cautions. There are no user-serviceable parts in this system.

Fuel Vents Marine Gas System Accessories. Under extreme circumstances such as a prolonged incarnation of the fuel tank the fuel level could cause both FLVV and Grade Valve to close. The purpose of these valves is to control the fuel pressure within the fuel system.

But in this situation pressure will build and with nowhere else to go. The fuel oil system for a marine diesel engine can be considered in two partsthe fuel supply and the fuel injection systems. Fuel supply deals with the provision of fuel oil suitable for use by the injection system.

Marine Fuel oil system includes various piping systems provided for bunkering storage transfer offloading and treatment of fuel oils. Fuel oil transfer system This system. NRCXRC 316Stainless Steel Marine Grade Boat Fuel Vent Universal 90Boat Flush Mount Fuel Gas Tank Vent for 58 Hose with Mounting Gasket Hardware Fitting 45 out of 5.

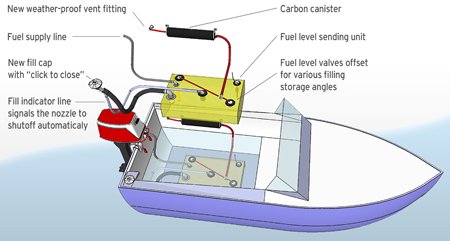

The system also needs to be designed to prevent the defeat of the tank ventilation system when parking a trailered boat on a steep hill when fuel in the tank might back up into the vent hose. Some new marine fuel systems carry charcoal canisters similar to those found in primary fuel tank vent systems in the automotive world. Made by Parker Filtration a leading maker of diesel fuel filters the LifeGuard LG100 three-stage separator is the most advanced vent-spill preventer we tested.

Rated for 50 gallons per minute gpm it is designed to collapse foam and return it to the tank as well as prevent surges from overfilled tanks. Inlet Check Valves ICV and Surge Protector. Fuel Demand Valves FDV Fill Limit Valves FLV Tank Vent Valves TVV AirFuel Separator and P-Trap.

EPA Compliant Sealed Gas Fills Diesel Water. Non-EPA Gas Fills Diesel Water Waste Deck Fills. The fuel inlet the fuel tank vent the opening for the level gauge and the opening for the pick up must all be on the topmost surface of the tank.

Drains are not allowed on gasoline tanks. Sight gauges are not allowed. Diesel tanks are allowed to have openings below the top of the tank such as a drain or sight gauges.

A typical permanent fuel system consists of. Fuel tank usually made of aluminum fiberglass or plastic Hold-down straps to secure the tank 1 ½ deck fill fitting including the gas cap 1 ½ fuel fill hose from the deck fill fitting to the fuel tank Thru-hull vent fitting allows fuel vapors to vent to outside of the boat. For filling and maintaining your boats fuel tank systems turn to the professionals at Wholesale Marine.

We carry an extensive line of boat gas tanks from leading manufacturers for both inboard and outboard engine fuel tank systems. Whether you need a fuel filter a fuel pickup tube a funnel for pouring a portable fuel tank a. Boat builders will generally install either a carbon canister or a 1 psi pressure relief valve in line with the fuel tank vent.

The marine canister manufacturer will provide the boat builder with the correct size canister specified for the volume of the fuel tank. Venting box has automatic deaerating valve the venting of HFO goes through a sight glass and is drained to overflow tank. Thus there is prevention of air lock into the fuel oil system which can be due to dissolved water in fuel or from the supply pump suction side.

Do not put air vents within 15 inches 381 cm of a fuel tank vent a fuel fill or an engine exhaust. Vapors will be sucked in or if near an engine exhaust carbon monoxide can enter the boat through the ventilation system. Also it is best not to.

Overfill protection is included with each system preventing the possibility of accidental system over-pressurization. Attwood systems are designed and configured to work with marine engines. Attwood has worked closely with Engine OEMs to validate our solutions and ensure that your systems are configured properly to work on your vessel.

Gas Tank Vent with Swivel Elbow. Chrome Plated Zinc Alloy Cap with Zinc Alloy Elbow. Black or White Polymer Splash Guards.

Removable 30 Mesh Stainless Steel Wire Screen Flame Arrestor - for use with fuel applications. Design Allows Elbow to be Rotated to any Position.