Just enough to fit on the piston. Rotate the crank so all 4 pistons are at mid stroke.

That percentage should be close to the same for all cylinders.

How to check piston rings with head off. If you had any doubts you should have done a compression check before you took it off the only way I know is just to visually check the bore and mic them topbottomradially feel the ridge at the top too of course this will only give you some kind of idea of the cylinder wear you cannot figure out the end gaps without a full teardown. If you do that you may as well rebuild it. Squirt a couple shots of oil in the spark-plug and try again.

If the numbers go up drastically then its good indication rings are week. If the number stay the same and the compression is low then it would point to the valves. A secondary leak down test with a differential compression tool would be next.

Easy way to check that are engines pistons rings OK or not. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features. Instead of recompressing smoothly like its supposed to something is causing that oil ring to hang up and exert excess pressure against that cylinder wall and its wearing a groove in the wall.

Youve got the head off its not that much more work to pull the pan. Pull the pan pop that piston out and check it out. The coolant might have run down onto the piston when you lifted the head up off the block.

If youre really worried about cracks in the head or block you can use a dye-penetrant inspection system to check for them. Heres one kit thats available. If each cylinder is within that range the piston rings are in working order.

If the gauge reading is low on a particular cylinder remove the compression gauge and squirt a small amount of water into the cylinder with a spray bottle then repeat the test. If the reading improves on that cylinder the piston rings are either worn or cracked. The piston ring can be checked without disassembling the engine.

The piston ring can be tested by following the step-by-step instructions discussed below. Step 1 Removing the Fuse. The fuel pump is controlled by a fuse.

You have piston ring gaps and those should allow the fluid to by-pass rather easily. There will always be some cylinder leakage. The correct way to test it is with the heads on and then to put in compressed are and test for rate.

That percentage should be close to the same for all cylinders. Just modify it for diesels. Once the head is off.

Rotate the crank so all 4 pistons are at mid stroke. Pour oil on tops of all 4 pistons about an inch or so. Let sit for several hoursovernight.

If they are good you will still have equall amount of oil on top of the piston. If one cyl is lower than the rest you stand a good chance of a ring issue in that hole. Piston Ring Pliers.

Position the ring on the expander and expand it. Just enough to fit on the piston. Do not over extend the ring.

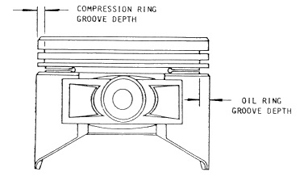

Position the rings so the end gaps are staggered 180 degrees apart. This will reduce blow-by. Always check ring groove depth to make sure the rings are the correct ones for the piston.

HOW-TO Unseize Piston RingsDont forget to click the to turn on Video Notifications for more money saving videos and tips featuring all the brands like S. Learn how to replace your head gasket and piston return springs so your car or truck can run and drive again. In this video I show you ho.

The piston to cylinder clearance should be checked every time you rebuild the top end. To check the clearance measure your cylinder with a bore gauge and micrometer then measure the piston in the right place and check the readings against the limits in your engines factory service manual. A more direct way to check if the piston rings are bad is to take a look at the them.

As we said before the piston rings are located around the piston head. You can look at their quality by seeing if they have any evident damage. Although they are made from durable metals they can be worn.

Piston Rings Blowby - Explained - YouTube. This property can be checked by pressing together worn and a new ring as in figure and observing whether the gap of the worn ring closes more than the new ring. How to Remove Fit the Piston rings.

The piston rings should be carefully removed from the piston either with a special removal and installation tool or with three brass strips. Always go by manufacturers specs when measuringsetting gaps. Run your cylinders down to the bottom and check for a ring ridge at the top of the cylinder.

If you can feel a ridge line you have wear. And should rebuild at some point. Check for carbon build up at the top of the cylinder where the piston ring stops.

Carbon here can indicate oil ring failure. Run your piston down half way and wiggle the piston. Therefore get your hands on the service manual to understand the concept in detail.

In a well-ventilated area use some kerosene and soak all the removed pistons into it. Use the piston ring tool and take out the old piston rings. Get a feeler gauge to check whether all the ring grooves are on the piston.