You may be able to get a loaner from a big box auto parts store. The head still has to be preheated and slow cooled after the crack has been filled.

Which Coolant to Use.

Coolant spraying from engine block. If youre having a large amount of coolant spraying under the left side of the engine of your Honda Accord its most likely caused by a ruptured coolant line. Possibly a bypass hose or the heater core hose. There is not a temporary fix for this issue that wed recommend.

The coolant expansion tank is there to capture the expansion of the coolant in the rest of the system. The spraying of coolant in the engine compartment occurs after the cooling system pressurizes. When pressure begins to build in the cooling system coolant will be forced out much like a spray nozzle from a water hose.

Fiesta MK5 2001 Endura-E 13 engine. Steam started coming up from under the bonnet yesterday and we discovered a small jet of coolant spraying from inside the engine. At first we thought it was the pipe heading in to the oil filler cap but on further inspection there is a hole in the engine block which is spraying out water when the engine is hot.

Soak up what coolant you can spray the bore with aerosol water repellant lubricant. Any coolant in the oil should collect in the botton of the oil pan and can be drained out with the oil. To get rid of the oil in the coolant a simple water flush may be enough but if you want to do a.

Finding the exact source is determined with a pressurized tester. It is a small hand pump that pressurizes the system and forces the coolant out at the leak point. You may be able to get a loaner from a big box auto parts store.

It is used with a cold system and the engine off so you can reach in with your hand to find the drip. Since then Ive replaced the upper and lower radiator hoses the radiator itself the smaller hoses that connect to the coolant reserve tank towards the back of the engine. This past week I was driving and the radiator light came on.

When I popped the hood to check it out coolant was spraying from the back area of the engine compartment. Engine Block Cleaning - YouTube. If playback doesnt begin shortly try restarting your device.

Flame Spray Welding. Another technique for repairing cracks in cast iron heads and blocks is flame spray powder welding. Flame spray welding is faster and easier than furnace welding and can create strong and long-lasting repairs the same as furnace welding.

The head still has to be preheated and slow cooled after the crack has been filled. Rinse all soap from the engine block and immediately coat all interior and exterior surfaces of the engine block with a lubricating oil spray to prevent the rusting process. Spray the inside of the block cylinder bores lifter bores oil galleries bearing journals and saddles.

And cooler pistons allow for a more aggressive tune. Installing the GETM Garage Piston Cooling System in the main webbing of the engine block allows for a cooling jet to spray the underside of the piston with oil and reduce piston temperature by flowing heat away. Spraying A Degreaser On The Engine Block.

One of the ways of knowing how to remove rust from inside engine block is using a degreaser to get rid of dirt oil and greases whenever you are cleaning your engine block. You can make use of wire-bristle brush or scraper to rub off any excess dirt or rust. A minor crack in the engine block can cause engine oil or coolant to slowly seep down the side of your engine.

It will look like its coming from nowhere at all or might even be just a spill. A tiny internal crack in your car engine may mean you find floating oil residue on top of the coolant in your radiator or your engine oil may look like chocolate milk. So the first sign of engine coolant leaks is usually an engine showing a low coolant indicator.

As a result this is followed by a high engine temperature reading or actual engine overheating. Usually the coolant can be seen dripping spraying seeping or bubbling from the leaky component. Seal the hose into the bottom stub.

Tie a long plastic bag with a hole in the bottom to the top stub to direct the coolant away from the engine and electrical components. This is achieved through the use of engine coolant and a radiator which removes heat from the coolant once it has passed through the engine block and cylinder heads. In time the engine coolant will need to be changed and flushed to help protect the engine gaskets seals and cooling system from corrosion which will cause coolant leaks.

How to repair an engine block or radiator leak with KW Block Seal - YouTube. How to repair an engine block or radiator leak with KW Block Seal. A water-cooled engine block and cylinder head have interconnected coolant channels running through them.

At the top of the cylinder head all the channels converge to a single outlet. A pump driven by a pulley and belt from the crankshaft drives hot coolant out of the engine to the radiator which is a form of heat exchanger. Unwanted heat is passed from the radiator into the.

So after scraping your engine block make sure it does not have any leakages. After all these use your rag to wipe off your engine block completely. You can do this by spraying the block with water or use a clean rag that has already been soaked for a while in hot water.

Finally use a dry rag to clean off any moisture on your engine block. Which Coolant to Use. See the discussion on Coolant Recommendations.

Block Drain Plugs Location. B230FTInquiry B230F - I want to flush the cooling system but the only block drain I see is a threaded male plug on the RH side of the block kinda high below exhaust manifold runners 1 and 2Is that all there is. Your vehicles head gasket seals the space between its cylinder head and engine block.

If the head gasket fails coolant and engine oil may mix. You may also notice that coolant is leaking from the bottom of the engine and dripping onto the ground. Either way a blown head gasket can be disastrous for your engine.

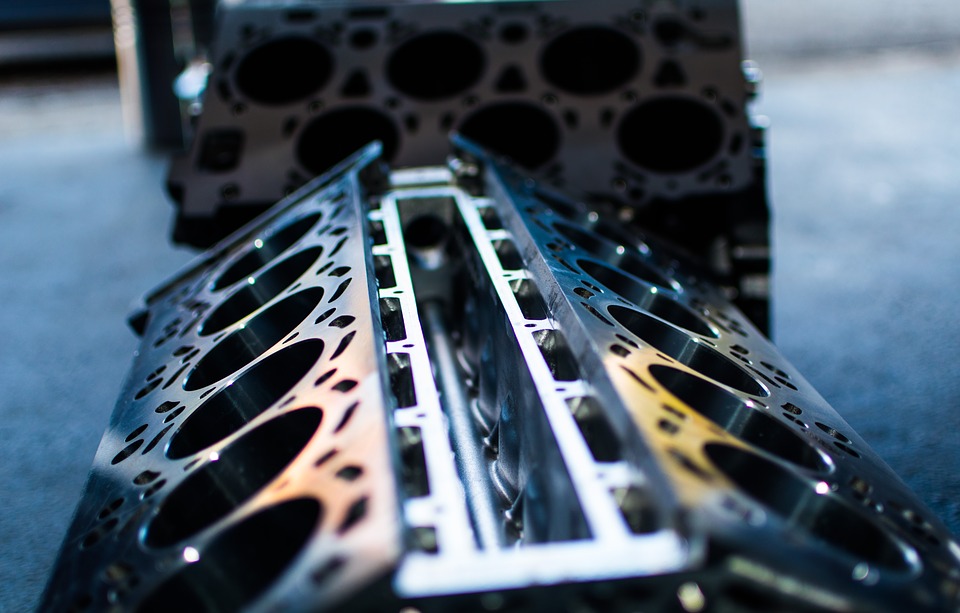

Pressure testing requires special plates and plugs to close off all of the coolant passages on a head or block. It also requires a large tank so the casting can be submerged under water. When air pressure is applied to the coolant jackets 30 to 40 PSI max you should see no bubbles coming anywhere from the casting.

The block material is typically JIS-AC4B shell molding or JIS-ADC12 high-pressure die casting. Bore pitch can be shortened in multi-bore engines. Quasi-monolithic linerless 7 Aluminum block with metal-sprayed bore surface.

Wire explosion or plasma spraying steel base alloy on the aluminum bore wall.